How Airport Safety & Jet Blast Testing Go Hand in Hand

We specialize in safety.

It’s in our name for a reason! OTW Safety is dedicated to designing and manufacturing the most outstanding and resilient high-quality safety products on the market. We want our products to stand the test of time (and anything else they might encounter!). So, we regularly test all of our barricade products to ensure that they are up to not only our standards, but the highest level of safety standards in their field.

We test for every extreme condition.

Concerned about weather? Our barricades can handle intense weather of almost any kind. We’ve done the field tests to ensure it!

In the construction business? We’ve got you covered. Our products used in high-traffic and high-speed areas have been extensively crash tested.

Need extra measures to safeguard against danger? Our security barriers are of the highest caliber. They even pass ballistics testing with flying colors.

Guiding hundreds of planes and pilots a day on the airport runway? Our low-profile barriers are designed for and tested against the harshest of conditions. They meet and exceed FAA regulations for jet blast testing.

We test our products with experts like SGS Polymer Solutions so that you know you’re getting the absolute best of the best; because safety doesn’t just matter – it keeps the world turning.

Airport runway safety is paramount.

Airports have high standards for their safety regulations on the airfield. The Federal Aviation Administration (FAA) requires that barricades in use on the runway specifically, must be “weighted or sturdily attached to the surface to prevent displacement from prop wash, jet blast, wing vortex, or other surface wind currents” in order to be considered “jet blast tested” and allowable for use on an airfield at FAA certificated airports (and highly recommended for those that aren’t).

Non-collapsible barricades are not allowed on runways, as concrete barriers, metal barriers, or railroad ties (all commonly used at airports in the past) would pose great risk to an aircraft if they were to be run over. As any barriers used on the tarmac must be collapsible in aircraft movement areas but able to withstand other forces (like those mentioned above), plastic is the material of choice in almost all cases. As we specialize in safety and plastic barricades, our airport barriers are the perfect choice for any airfield.

In order to keep operations running smoothly and safely, barricades are necessary. They are used to identify hazards for pilots and those in elevated positions (i.e. the control tower). They provide clear delineation of pathways, as well as guide construction personnel and ground crews safely. Without these barricades, potential dangers could be left unchecked, posing immense risk to personnel and aircraft alike. With bright colors, secure flags, and warning lights (all while allowing for night visibility and wing-tip clearance) – airport barriers and barricades safeguard the entire airfield from serious accidents. This helps pilots, ground crews, and airport staff keep operations running smoothly – ensuring the runway is the safest it can be.

How do we jet blast test… and why?

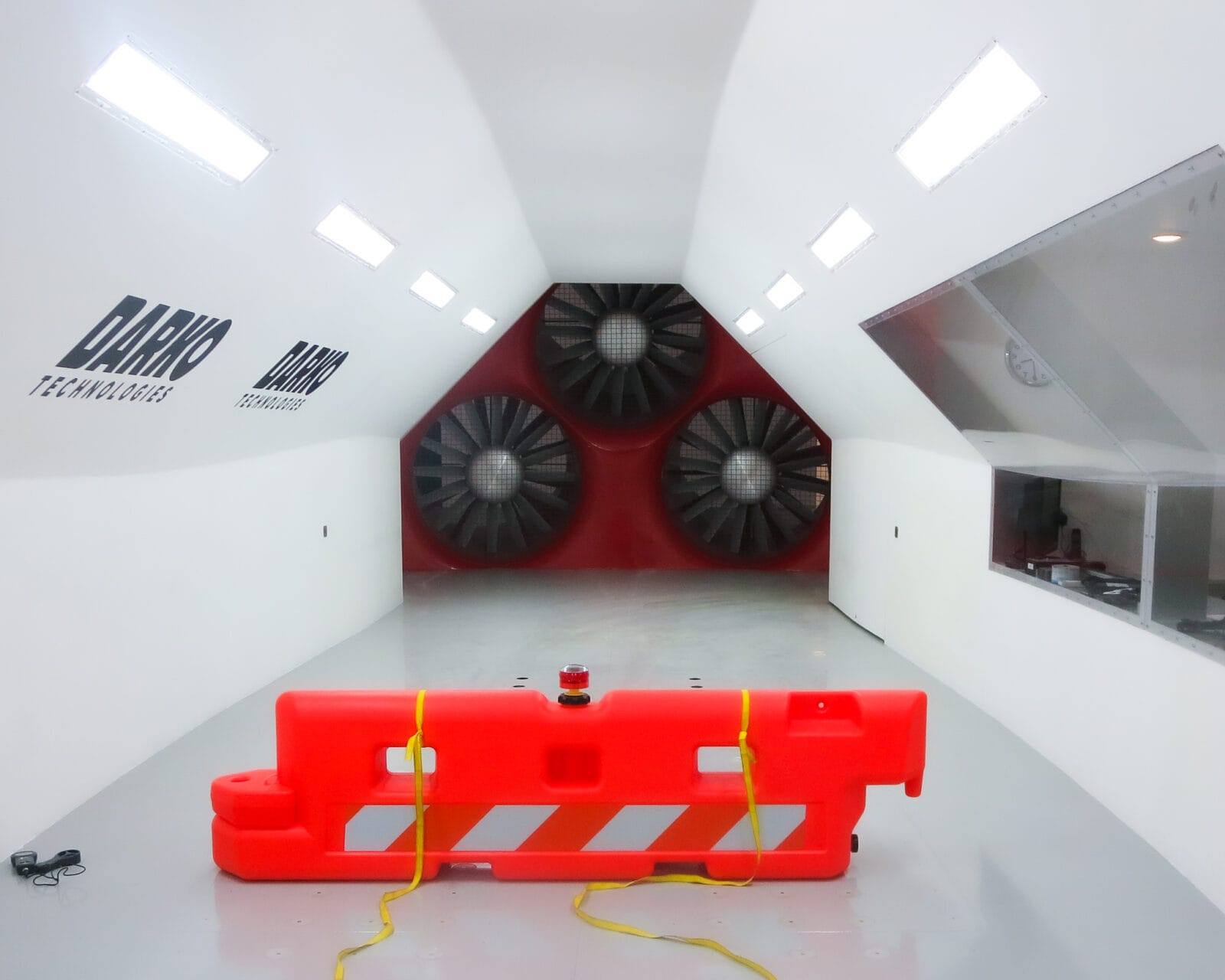

We specifically engineered our low-profile airport barriers to meet (read: exceed) FAA regulations. In order to be certified as “jet blast tested” and FAA compliant, we took them to the wind tunnel experts at Darko Technologies to test their mettle against wind speeds of up to 70 miles per hour. As jet blast speeds can reach that velocity within seconds, even in idle or while taxiing, it’s incredibly important to have safety barriers that can withstand the force and temperature they produce. Anything less would become a hazard in itself in active aircraft zones. We frequently use third-party testing and always ensure that our results are never biased. We trust Darko Technologies to get the job done whenever wind tunnel testing is needed!

Here’s how our Airport Barricade Jet Blast Resistance Test is run:

The 10-inch low-profile airport barricade is set up within a wind tunnel – flags and hazard lights attached – and blasted with air at three different speeds for 2 minutes each. At 35 miles per hour, the barriers either pass or fail in whether they move at all. At 45 and 70 miles per hour, movement, if any, is noted. In regard to our most recent testing, all barriers were immovable at every wind speed – jet blast testing success achieved!

Our continued commitment to airport safety

The success of this test is not unusual for OTW. We are dedicated to ensuring that every single product we put on the market is thoroughly and rigorously tested for safety, durability and reliability, and our airport barriers are no exception. Our multi-use barriers are versatile and ready for anything (like airport construction) and fully adhere to FAA regulations for airfield safety – they are ingeniously designed to withstand excessive force, and are highly visible (especially with optional hazard flags and red solar hazard lights). They interlock with a patented FOD (Foreign Object Debris)-free feature, and are manufactured from long-lasting, UV-resistant material. Not only does our 10-inch airport barricade pass and exceed the Federal Aviation Administration’s regulations, it also is federally certified by the Department of Defense (DoD) and complies with their Unified Facilities Criteria (UFC) 3-260-01 “Airfield and Heliport Planning and Design”.

We mean business when it comes to airport safety, so we take every measure necessary in order to meet regulations – including jet blast testing – and are proud to carry a one-of-a-kind, FAA and DoD compliant barricade to help airports keep their airfields the safest they can be.

“We can’t say enough great things about how their products assisted the safe and efficient operation in and out of our airport’s East Ramp (Special Olympics Airlift). Using the low profile airport barricades to denote each arrival lane ensured each pilot knew exactly where to go and that their aircraft was properly marked for ground crew operators.

We look forward to the continued use of our durable high quality low profile barricades on future airport projects and events!”

Gary Trotta, A.A.E.Manager, Orlando Executive Airport