10″ Low-profile Airport Barricade

Low Profile Barricades

Since 1999, airports worldwide have trusted the AR10x96 Low-profile Airport Barricade to warn pilots of airfield hazards, ensure traveler safety, and keep airport construction sites safely delineated. Designed to maintain the critical wingtip clearance necessary on an active airfield, the AR10x96 is easily visible and identifies hazards for pilots and other individuals in elevated positions.

Request a QuoteDescription

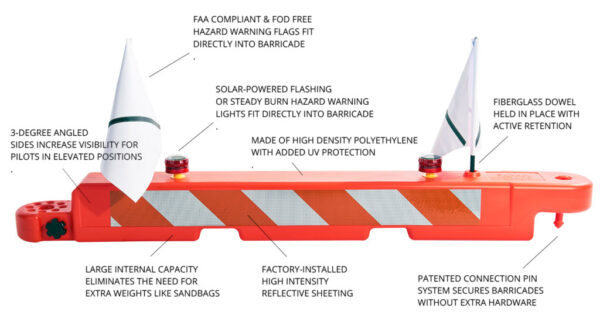

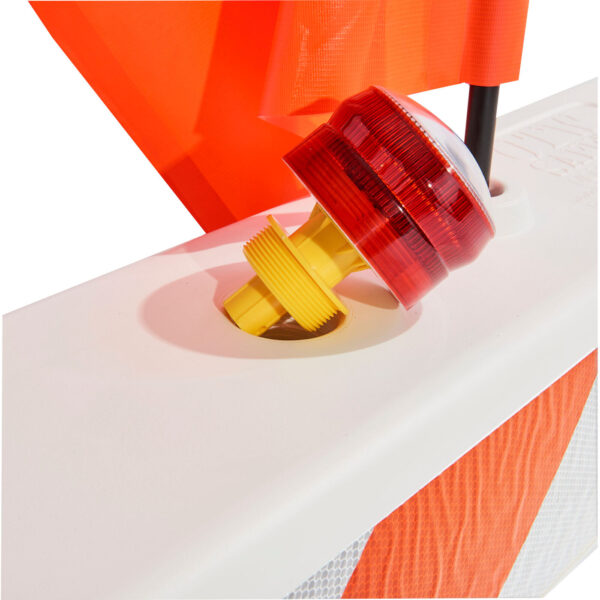

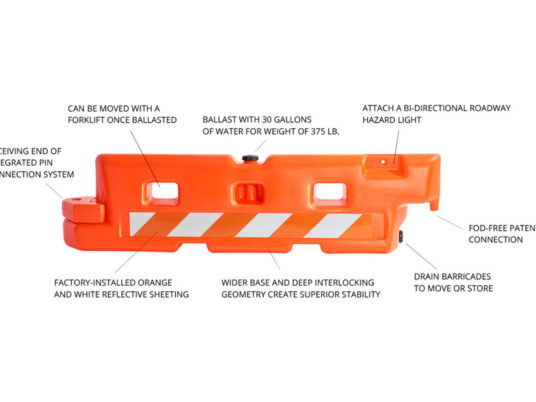

The OTW low-profile airport barricade is one of a kind and designed with airfield safety in mind. Connect low-profile barricades without additional hardware thanks to the built-in interlocking pins, and easily accommodate two hazard lights with the threaded fill-holes. Need hazard flags? Active retention holds the fiberglass flag dowel in place for a truly FOD-free hazard indicator.

As it exceeds FAA and MIL-STD requirements for its genre, the AR10x96 is frequently written into project specifications. Third-party jet-blast testing was passed with flying colors; when filled with water, the barricade will remain in place – even when kitted with hazard lights and flags – unaffected by prop wash, jet blast, or surface winds up to and above 70 MPH.

As it represents the safest way to delineate airfield hazards, the AR10x96 is used at major international airports across the U.S. and abroad. Boasting 3-degree angled sides, reflective sheeting, engineered UV protection, and a patented FOD-free connection system, these low-profile barricades have no equal.

FEATURES & BENEFITS

- Integrated connection design and large internal ballasting capacity eliminate the need for external weights (i.e. sandbags)

- Exceeds wingtip clearance safety standards

- Includes factory-installed high-intensity orange and white reflective sheeting at no additional cost

- One-year manufacturing defect warranty

FEDERAL CERTIFICATIONS

- Meets FAA AC150/5370-2G “Operational Safety on Airports During Construction”

- Meets DoD Unified Facilities Criteria (UFC) 3-260-01 “Airfield and Heliport Planning and Design”

- “Buy America Act” Compliant

Applications

Airport Construction Projects, Parking lot delineation, construction projects, go kart tracks

Trusted By

Specifications

COLORS

- Safety Orange

- White

- Custom colors available (minimum purchase required)

COMPOSITION

- UV-resistant High Density Polyethylene (HDPE)

- Blow molded

- Reflective sheeting (6 in x 72 in / 17.8cm x 183cm)

SIZE

- Height: 10 in / 25.4 cm

- Length: 96 in / 2.44 m

- Width: 10 in / 25.4 cm

WEIGHT

- Empty: 19 lb / 12.7 kg

- Full: Apprx 270 lb / 122.5 kg*

*Weight calculation based on 30 standard US gallons of water

OPTIONAL ACCESSORIES

- Two solar hazard lights

- Two hazard flags

NSN Reference & Corresponding OTW Part Numbers

- NSN 5660-01-464-7545

- OTW AR-10×96 – Orange/White