OTW Safety Low-Profile Barricades Utilized in Ford International Airport Reconstruction Project

This month, OTW Safety was featured in an article for the industry-leading magazine, Airport Improvement, which outlined the recent reconstruction project at the Gerald R. Ford International Airport in Grand Rapids, Michigan. The $50-million-dollar construction project spanned over 167,000 square yards of apron pavement. The project initially began in 2018, concluding earlier in 2021, all while maintaining normal airport operations.

Notably, the planners and construction crews at the Gerald R. Ford International Airport utilized OTW Safety’s low-profile barricades throughout the construction process. The barricades were primarily used to delineate work areas located on “active movement areas” of the apron. The project involved expanding and widening eight gates, building a new Federal Inspection Station, and relocating a traffic control tower. Over this time, the airport experienced significant growth in traffic and this project was able to expand its capabilities and improve existing facilities.

OTW Airport Barricades

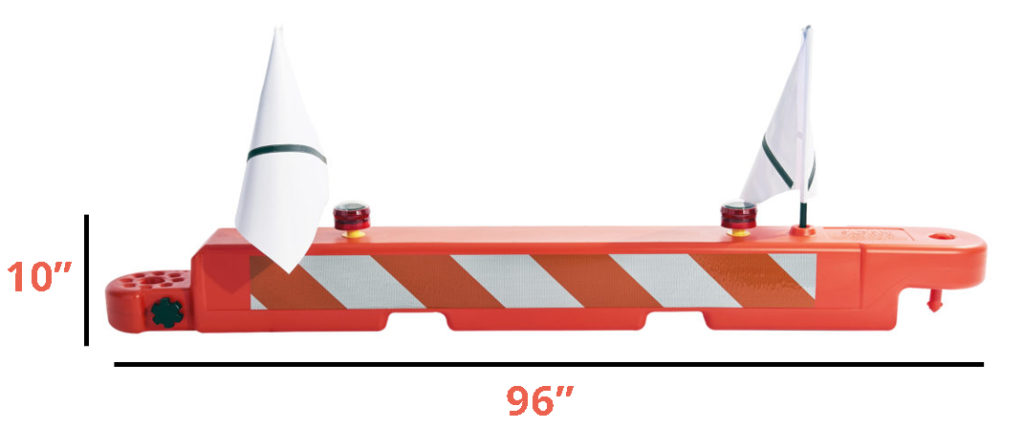

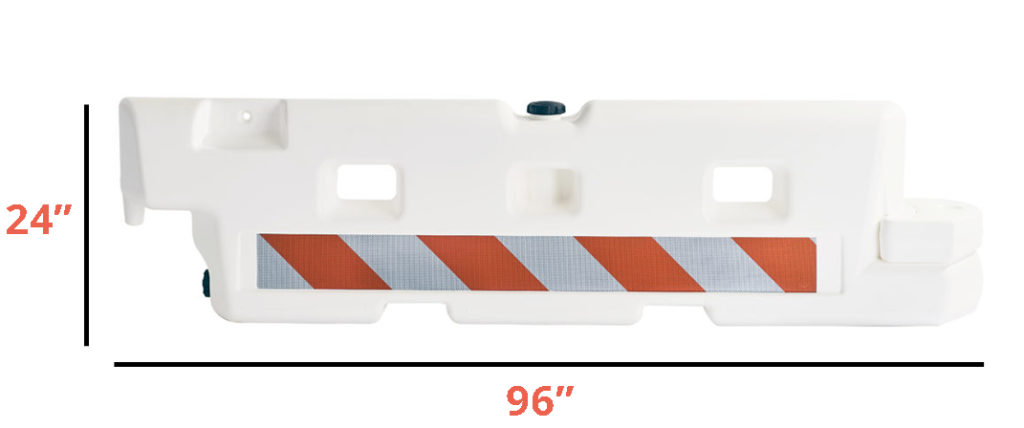

OTW Safety has worked with airports for over 20 years to supply them with highly effective, durable, and reliable safety equipment for a wide variety of projects. OTW offers several barricades and accessories designed specifically for airports –– the 10″ low profile airport barricade, the 24″ low profile barricade, and helpful add-ons like the airport delineator and barricade flags.

The 10″ low profile airport barricade is FAA compliant and includes factory-installed high-intensity reflective sheeting. Our airport barricades are jet-blast tested and this model –– the AR10X96 –– is often written directly into project specifications. That’s because it exceeds FAA and MIL STD requirements. The 10″ low profile airport barricade stands up to prop washes, jet blasts, and surface winds in excess of 70 miles per hour.

Similarly, the 24″ low profile barricade (AR24x96) is typically used to designate large airside construction zones. It boasts many of the same features as the 10″ low profile, but is even bigger and therefore even more visible to pilots and construction workers.

Our products are built with durability and safety in mind. That’s why all OTW airport safety barricades come in easy-to-spot safety orange and are designed to accommodate a number of additional safety features such as hazard warning lights and flags. Additionally, all our barricades have the ability to interlock together to form continuous lines. When it comes to creating secure construction zones at highly-sensitive areas like airports, quality safety barricades are essential to sectioning off work areas.

Portability without compromising effectiveness is one of the key advantages of plastic barricades. Our airport barricades are lightweight enough when empty to stack, move and store with relative ease. However, they can be ballasted with water to greatly enhance their strength and weight once set in place. Any project that requires regular movement and flexibility will benefit from barriers that are versatile and portable.

The OTW Difference

At OTW, we don’t just sell high-quality airport barricades— we design and manufacture them ourselves. Our products are made right here in the USA, and it’s our mission to offer our partners superior and sustainable products and services. For more information about our line of airport safety products, contact us here.