How to Mitigate Hazards From Runway Construction

As airports around the world see an increase in traffic and must adapt to meet safety requirements accordingly, they are constantly undergoing construction. Unlike other spaces, airports have to continue operating as usual even while undergoing construction projects, which can be hazardous for airport employees, passengers, and air traffic operations as a whole. Determining how to mitigate hazards from runway construction is important in keeping airports operating safely and efficiently, even while undergoing such projects.

To mitigate hazards from runway construction, airports utilize tools like safety barriers to warn pilots of airfield hazards and ensure the safety of travelers. OTW Safety has been in the business of improving airport work zone safety since inventing the world’s very first plastic low profile safety barricade, and is the #1 airport safety product manufacturer, with our products keeping travelers safe in airports around the world. Learn more below about the trusted OTW products used daily by distinguished international hubs such as Dublin International, JFK, Tijuana and Guadalajara airports.

Safety Barriers

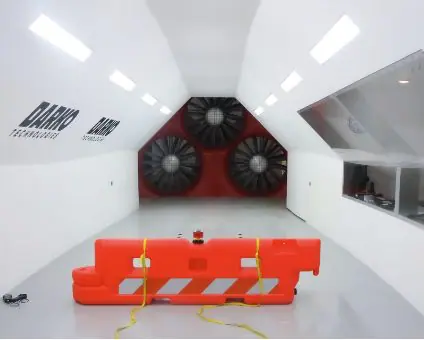

Our AR10x96 low profile barricade meets the safety needs of airports by identifying potential hazards for pilots and other airport employees while maintaining critical wingtip clearance, crucial for keeping everything running smoothly as an airport continues normal runway operations. These low-profile barricades feature built-in interlocking pins, allowing them to connect without additional hardware. Each barricade also includes custom fill-holes to accommodate two of our hazard lights and flags, which can be added to our barriers as an added safety measure. The AR10x96 has undergone jet blast tests and will remain in place and ultimately unaffected by external factors including winds over 70 MPH. Our one-of-a-kind low-profile barricades are the safest and most effective way to mitigate hazards from runway construction.

Our AR24x96 barrier is commonly used as a safety measure within airside construction zones, to protect workers and travelers alike. Able to withstand extreme conditions within restricted airport zones and alongside powerful aircraft, the AR24x96 is designed to be highly visible to pilots in larger airplanes.

Safety Lights and Flags

In addition to our barriers which effectively add a sense of safety to runway construction zones, our airport lights and flags can serve as an added safety measure. These highly visible markers can be easily attached to our safety barriers without additional fasteners or bolts and can withstand extreme conditions like jet blasts and powerful winds. Our safety lights are solar-powered, making them both cost-effective and environmentally friendly while directing light upwards to draw the attention of pilots and other elevated crew members. OTW is committed to the safety of travelers and flight staff alike, especially in conditions when additional precautions like lights or flags are needed to due conditions that cause low visibility.

Delineator

OTW’s low-profile Delineator serves as an effective alternative to lightweight traffic cones. Once filled with water, the Delineator can weigh up to 45 lbs, making it the perfect safety barrier to withstand surface winds, jet blast, prop wash, and other hazardous environmental elements. The Delineator’s high-intensity orange and white reflective sheeting creates superior visibility for both pilots and ground workers, keeping them safe.

Contact Us Today

When it comes to mitigating runway construction hazards, OTW Safety is here to make your life easier by ensuring that operations run smoothly. For more information on our innovative safety barriers or safety lights and flags, contact us at (801) 363-7740 or orders@OTWsafety.com.