Contract Manufacturing and OTW Safety

Plastic manufacturing has taken the world by storm in the last few decades and with good reason. It is cost-effective and creates durable and lightweight products. Plastic also has the benefit of being low waste and easily recyclable, with PET (polyethylene terephthalate) and HDPE (high-density polyethylene) likely being the easiest to recycle.

What is plastic manufacturing?

Raw plastic material has incredible potential, and plastic manufacturing takes those polymers, resins, and additives and transforms them into usable, finished products. Production takes place in stages, from design and engineering to molding and assembling.

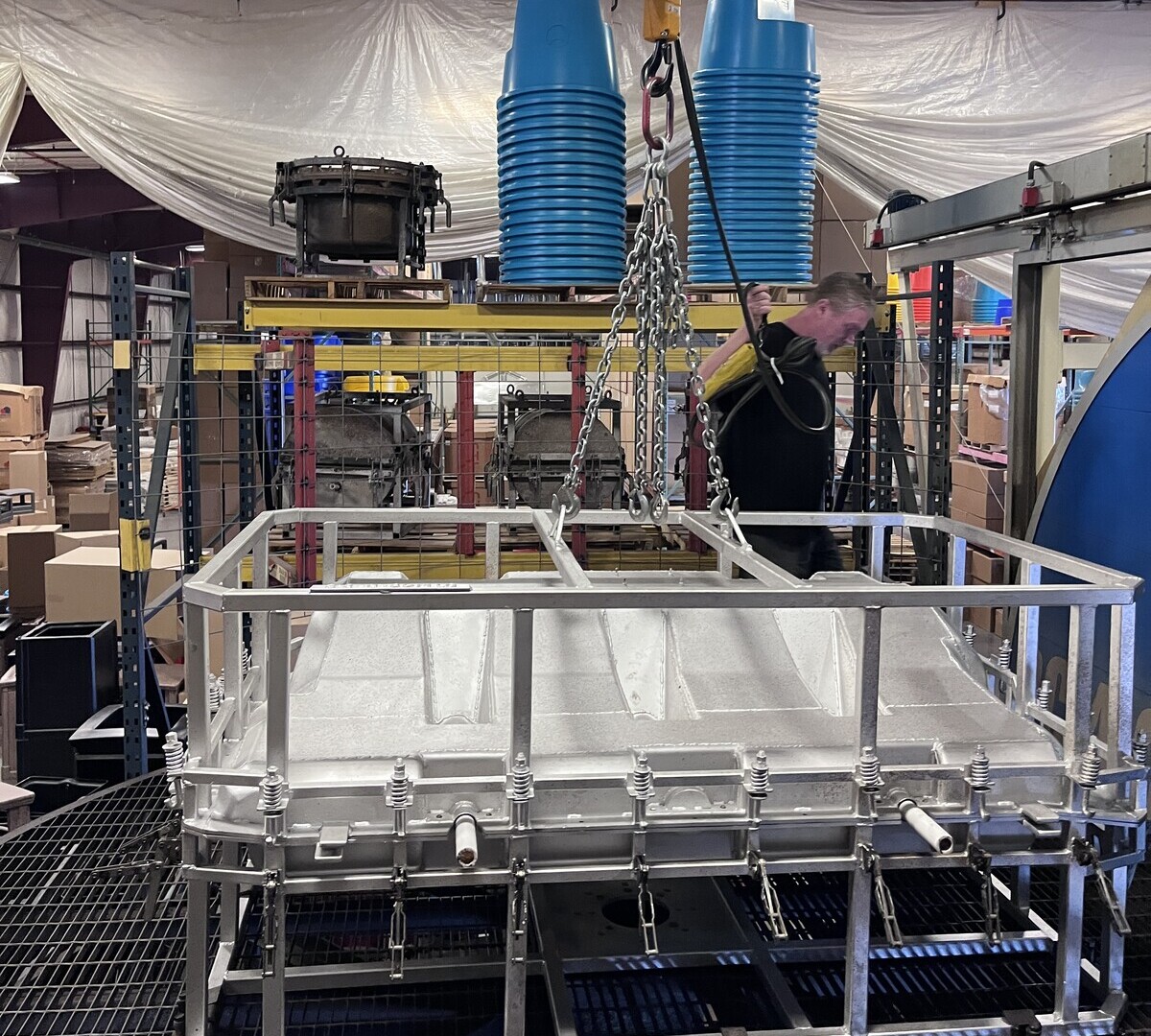

While there are many types of techniques used in plastic manufacturing, OTW focuses on rotational molding, blow molding, and injection molding.

Rotational Molding

To create a product via rotational molding, a mold of the necessary part(s) is first created. The mold is then attached to the manufacturing machine, plastic is added, and the mold is slowly heated and rotated both vertically and horizontally. This slow and steady process ensures that the plastic is evenly distributed, which forms one seamless, cohesive piece (learn more here!).

Blow Molding

Blow molding, on the other hand, is closer to glass blowing in technique. The plastic is heated and most commonly formed into a parison (a thermoplastic hollow tube); then, the parison is secured to the mold. Hot air is blown across or onto the mold, which redistributes the plastic throughout the interior of the mold cavity. This creates a hollow object, such as a bottle or some of our very own barricades.

Injection Molding

Injection molding is the final technique that OTW uses to create plastic products, and it happens just like it sounds: products are created by injecting molten plastic into molds under high pressure, then cooling, solidifying, and removing them.

Plastic manufacturing made streamlined and affordable.

Innovative products are imagined every day, but taking an idea from conception to mass production has the potential to be daunting and complicated. While thinking of the initial idea might be somewhat straightforward, bringing a new product to life requires technical skills, specialized software, and expensive machinery. Business owners, managers, and creative teams have incredible ideas when it comes to creating new products for their brand, but taking it from point A to point Z requires more than just great ideas. From conception to the drawing board to mock-ups to edits to manufacturing, it takes a lot to make a new product and can get very expensive, very quickly.

Here’s where OTW Safety comes in.

Collaborating with a contract manufacturer (that’s us!) simplifies this process by reducing upfront costs and expediting product development. This option is ideal for businesses or individuals who do not have access to the tools, skills, or machinery needed to produce their own goods.

At OTW Safety, we possess over 25 years of experience in plastics manufacturing, including rotational molding, injection molding, and blow molding. These distinct manufacturing methods each have their own advantages and are utilized to create high-quality plastic products. By entrusting the production of their items to a contract manufacturing company, businesses can obtain well-crafted products without the need to invest heavily in their own factories and equipment.

But here’s where we’re different than other contract manufacturers: we’ll take you through the process from start to finish, rather than only manufacturing your product after it’s been designed. We’ll help with the first steps of ideation all the way through getting your product out on the market – we have an in-house engineer and design team ready to assist in every aspect of your product from A to Z.

Not sure about outsourcing your project baby to someone else? Not to fear! Our team has a background in safety engineering and continually works within strict requirements (like those of the FAA) to ensure that our products are exceeding standards. We apply the same care and attention to detail to every project that comes to life under our roof, including yours!

With OTW Safety as your contract manufacturer, you can rest assured that your products are consistent, cost-effective, and cared for. You also guarantee a few more things:

- You can be proud that your product is made in the USA and not mass-produced in overseas factories

- You save $$ → by contracting OTW Safety, you don’t have to worry about the costs of warehouses/factories or investing in heavy machinery.

- We know our way around the block → whether it’s rotational molding, injection molding, or blow molding, we have the expertise to take it on. We’re plastics manufacturing experts!

Whether you’ve got a full product drawn up, or are just in the beginning phases of dreaming up the perfect product, OTW Safety is the best partner when it comes to contract manufacturing.

Ready to get started? Contact our experts today – we can’t wait to hear your idea and see it take shape!