Plastic Barriers: Are They Sustainable?

Here at OTW Safety, we take pride in the quality of our plastic barriers. That’s why all of our products use plastic that is durable, impact resistant, and recyclable. Whether it’s High-Density Polyethylene (HDPE) or Linear Low-Density Polyethylene (LLDPE), both plastics provide unique benefits for our different plastic barriers. So, why have we chosen these types of plastic over others and what are their benefits?

Types of Polyethylene

Take a minute to think about everything in your life that is made out of plastic. It’s a lot, right? From water bottles to parts in your car, plastic is an essential component of many items. There are various types of plastic, each with different advantages. The most common type of plastic is polyethylene (PE). This type of plastic is used in a variety of products because of its ability to be manufactured at different densities. A few common PE densities are:

Low-Density Polyethylene (LDPE)

Low-Density Polyethylene (LDPE) was the first polyethylene to be produced in 1933 and is still commonly used today. LDPE is a weaker type of polyethylene, with lower tensile strength. As the name suggests, LDPE has a lower density and is quite resistant. LDPE is also flexible, used commonly for plastic bags, plastic wraps, and six-pack rings found around cans and bottles of soda.

Linear Low-Density Polyethylene (LLDPE)

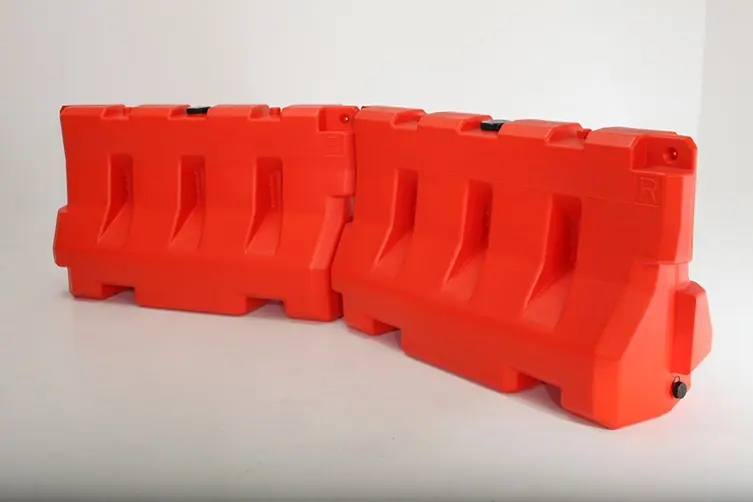

Linear Low-Density Polyethylene (LLDPE) is a blended form of LDPE. It is the most flexible type of polyethylene but has more tensile strength than LDPE. LLDPE is very strong and absorbs impact extremely well, without tearing or puncturing. LLDPE is used in a variety of products such as toys, pipes, buckets and containers, and of course our Roadway Construction and Security Barricade product lines.

Medium-Density Polyethylene (MDPE)

Medium Density Polyethylene (MDPE) is the least common type of PE. MDPE is stronger than LDPE and has good shock and drop resistance properties. It is also highly resistant to chemicals and very stable. MDPE is commonly used for plumbing, pipes, and packaging.

High-Density Polyethylene (HDPE)

High-Density Polyethylene (HDPE) is the most versatile form of PE. It can be used in a wide variety of products, from water bottles to hard hats to our own Airport, Traffic, and Crowd Control barricades. HDPE is the strongest, toughest, and most chemical resistant PE. It is also the least flexible of the four PEs mentioned here. These properties make HDPE very long lasting and weather resistant. It can endure higher temperatures and resist mold, mildew, rotting, and insects. On top of that, it is the most UV resistant, with a special ultraviolet stabilizer added. Our 42″ Jersey Shape LCD Barricade, shown below, is made of HDPE.

Recycling

By using LLDPE and HDPE in the manufacturing of our plastic barriers, our products are long-lasting and environmentally friendly. Both types of PE are recyclable and are often repurposed for other useful items. If you notice, the triangle symbol found on plastic containers and products is used to inform consumers about recyclability. For different types of plastic, there are 7 different standard classifications for recycling purposes. Unlike commonly thought, not all plastics are easily recyclable. The types of PE we use to make our products, HDPE and LLDPE are both 100% recyclable.

We wanted to ensure that our business was environmentally conscious and sustainable, which is why we chose to use HDPE and LLDPE for our plastic barriers. HDPE has a resin identification code of 2 for recycling. HDPE is the most commonly recycled plastic and is considered one of the safest forms. Recycling HDPE is fairly simple and inexpensive, making it a great option for reuse. After recycling, HDPE is used for picnic tables, park benches, waste bins, and more.

LLDPE has a resin code of 4 for recycling. LLDPE is not as commonly recycled as HDPE, but can still be recycled. It is even getting easier to recycle HDPE. More and more communities are recycling LLDPE. It is considered less toxic than other plastics and safe for use. When recycled, it can be used for plastic lumber, garbage can liners, and floor tiles.

Final Thoughts

If you are looking for any type of plastic barrier, it’s important to understand the life cycle, materials, and sustainability of the product. Barricades should be made to resist weather, impact, and sunlight, staying in-tact, vibrant, and strong for years. We make our plastic barriers out of the highest quality materials, ensuring a long product life and cutting costs for your business. Our products are also highly sustainable and can be recycled and reused. If you would like to learn more about our various types of plastic barricades, contact us today, we would love to hear from you!