OSHA Barricade Safety Standards Summarized

What are the general OSHA barricade safety standards? These standards depend upon specific application, area of usage, and type of barricade.

The federal government and its agencies have created extensive lists, ordinances, and laws to protect the safety of all U.S. citizens. A great example of this revolves around OSHA (Occupational Safety and Health Administration) and all of its safety regulations in regards to labor conditions. Keeping workers, laborers, and citizens safe are paramount to OSHA’s overall mission. Protective barriers, barricades, and other traffic control devices like the ones we manufacture here at OTW Safety, all fall under this agency’s jurisdiction. Whether the barriers are plastic, concrete, metal, or any other kind of material, certain safety standards must be met.

What is an OSHA Barricade?

OSHA discusses two main types of barricades – rail barricades (Type 1, 2 & 3) and traffic control devices (like our longitudinal channelizing devices).

Rail barricades are defined as “a barricade is a portable or fixed device having from one to three rails with appropriate markings and is used to control road users by closing, restricting, or delineating all or a portion of the right-of-way.”

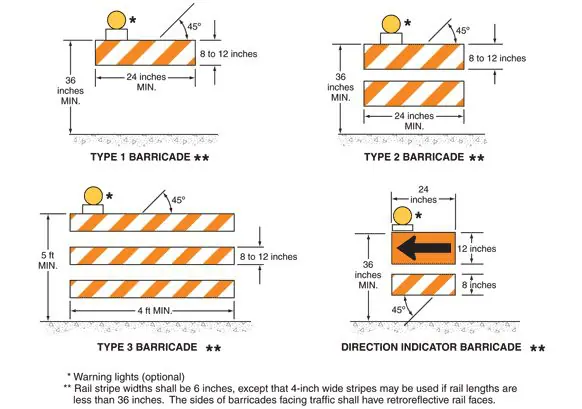

Stripes on a portable barricade must be orange and white with retro-reflective markings (which means light returns back the direction it came from), and these stripes must be at a downwards forty-five-degree angle, depending upon the traffic direction. The angle and direction of stripes depend upon whole lane placement, shoulder placement, or other varying situations.

(Source: https://mutcd.fhwa.dot.gov/htm/2009/images/fig6f_07.gif)

These barricades come in three main grades: 1, 2, and 3 type barricades. Types 1 and 2 have to be a minimum length of two feet, while type three barricades must be a minimum of four feet in length. Likewise, minimum thirty-six inches for the height for the former two barricades and five feet minimum height for the latter.

OSHA defines traffic control devices as “channelizing devices that warn road users of conditions created by work activities in or near the roadway and guide road users. Channelizing devices include cones, tubular markers, vertical panels, drums, barricades, and longitudinal channelizing devices” (page 58)

OSHA Barricade Standards

In general, barricades should always be properly supported and positioned to be visible and resistant to being blown over. According to OSHA, “at points of hazard, construction areas shall be posted with legible traffic control signs and protected by traffic control devices.”

If you want to get to more specific standards from OSHA, here is a quick summary (find the full summary on page 58 here). Here’s a quick look:

- Devices used to channelize pedestrians shall be detectable to users of long canes and visible to persons having low vision.

- Where channelizing devices are used to channelize pedestrians, there shall be continuous detectable bottom and top surfaces to be detectable to users of long canes. The bottom of the bottom surface shall be no higher than 2 inches above the ground. The top of the top surface shall be no lower than 32 inches above the ground.

- A gap not exceeding 2 inches between the bottom rail and the ground surface may be used to facilitate drainage.

- Warning lights may be added to channelizing devices in areas with frequent fog, snow, or severe roadway curvature, or where visual distractions are present.

OSHA Barricade Summary

There is much to keep in mind when learning about temporary traffic control standards and how to implement them to OSHA standards. Always keep in mind:

- Correct Type – The correct type of barricade should be used depending on the area and application.

- Visibility – Barricades should be positioned and elevated to be easily seen by pedestrians and drivers.

- Supported – Proper ballasting and support should be used to keep barricades upright and visible, especially when used in windy and high-speed conditions.

If you would like to learn more about safety barricades and their many applications, contact OTW Safety, the trusted safety experts.