Airport Beacon Lights: What’s important?

Let’s talk airport beacon lights

Our newest product, the LED rotating beacon, is a staple for airports across the globe. Versions of this navigational aid have been in circulation since the 1920s (did you catch our Meet the Rotating Beacon Light post?). These lights are essential for flying, especially during the night, and every airport, heliport, and military station uses rotating beacons to help their pilots fly safely.

The Federal Aviation Administration (FAA) has strict guidelines concerning most, if not all, operating systems, safety measures, and personnel at airports. Airport beacon lights falls under the “navigational aid” category and has requirements and regulations much like any other facet of an airport.

Regulations are key to safety.

Per the FAA, the number of flashes output per minute by the light indicates to pilots what type of airport or heliport they are approaching: airports, landmarks, and points on federal airways are identified by 24-30 flashes per minute, while heliports receive 30-45 per minute. To further identify the specific type of airport, alternating color codes are used. They are as follows:

- Lighted heliport: green, yellow, and white

- Hospital and emergency services heliport: white, green, and red

- Lighted land airport: green

- Military airport: white, white, and green

- Lighted water airport: white and yellow

- Lighted land airport: white and green

According to FAA Advisory Circular 150/5345-12F, the “effective intensity of a flashing light is equal to the intensity of a steady-burning (fixed) light of the same color that produces the same visual range under identical conditions of observation”. While a steady colored light might theoretically be useful in denoting a specific type of venue, the alternating of colored and/or lights at specific flashing outputs is a more precise way of indicating to pilots where they are headed. This is incredibly important and one of the most specific guidelines concerning rotating beacons.

In addition to the number of flashes and the color codes, the FAA has strict guidelines informing how a beacon is cared for.

While the Circular Advisories about the care and maintenance of a rotating beacon light are numerous and can be lengthy, here are a few of the most pertinent topics.

Color and weatherproofing

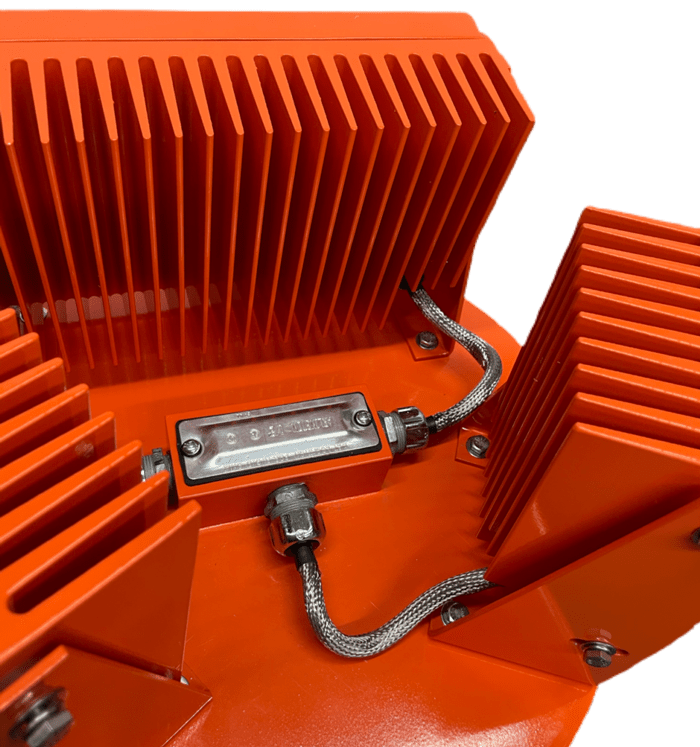

The tower and beacon must be painted with a primer and orange (international orange, color number 12197) or yellow (aviation yellow, color number 13538) as per AMS-STD-595 (Colors Used in Government Procurement, updated 3/11/2021), or a polymer powder coating with equal corrosion resistance, cadmium plating, or galvanizing in the same colors may be used. The paint or polymer powder is to protect against corrosion and environmental factors such as intense weather (wind, snow, rain), solar radiation, and high temps, while the bright colors ensure that the towers and beacons are visible both in daylight and at night. OTW easily meets these requirements, as each and every beacon is painted in powder-coated international orange for high visibility, weather protection, and corrosion resistance (the main factor covered under weatherproofing by the FAA).

Daily functionality

Due to the high level of usage, each beacon should be inspected daily for functionality. Dusk to dawn operation as well as the correct number of flashes per minute (rpm), correct colors, and flash sequence should be verified each day. This ensures that the beacon light indicates the correct type of airport, as well as proper visibility.

Regular maintenance

The glass in any rotating airport beacon should be inspected twice a month to ensure it is clear. As the opacity of the glass will affect how the light disperses, it is important to keep them as clean as possible for maximum clarity. Other items that need to be checked bi-monthly are the clutch, lens retainer, telltale light or relay (this indicates if the lamp has gone out), other relays, and the lamp changer or slip rings if they are equipped. Electrical components and connections must be inspected every year to ensure proper fit and function.

Daily, bi-monthly, and yearly checks are essential for maintaining the optimal operation of each beacon light; they ensure that each is functioning as it should and help maintain what can be a large investment. OTW makes this easy with the intuitive design of each beacon!

Lamp requirements

FAA AC 150/5340-26C specifically denotes a variety of requirements for the maintenance of airport visual aids, and rotating beacon lights fall under that category. Regarding the lamps used, specifically, the FAA AC discusses that the lamps used for each should be rated for a minimum of 4,000 hours of life at a voltage at or below 600 volts.

The AC also notes that traditional halide lamps, which are the most common type of lamp currently used since the transition from traditional incandescent lamps, have a lifespan of 22,000 hours but do take approximately 4-5 minutes to come to full brightness. If one is shut off during a time when it needs to be lit, for whatever reason, a halide lamp will take approximately 12-15 precious minutes to cool off and come back online, making those minutes a hazard for anyone flying at night.

OTW airport beacon lights use LED lamps and come to full brightness immediately, effectively banishing any downtime and potential hazards. OTW beacon lamps also have a typical lifespan of 50,000 hours, or 12 years, which is over double the typical lifespan. A halide lamp will often decrease in lumen intensity after two to two and a half years and must be changed, according to the FAA. While regular checks must still be made on an OTW beacon for the proper brightness, etc., you get double the usage of a traditional lamp. This means decreased cost in replacement lamps and less maintenance overall!

Talk safety to me.

OTW is proud of the strides that we take each day in bringing the best safety products to your door and the tarmacs of airports across the globe. With intentional design, in-depth research, and excellent partners, we are able to ensure that we are helping make the world a safer place one product at a time.

Ready to invest in a rotating airport beacon light (or any other OTW safety product)? Give us a call today!