Description

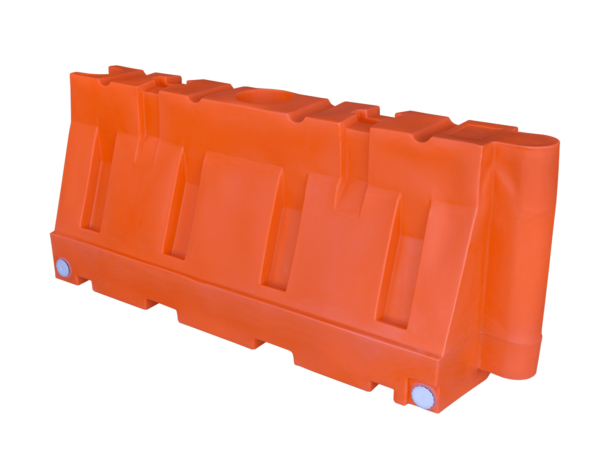

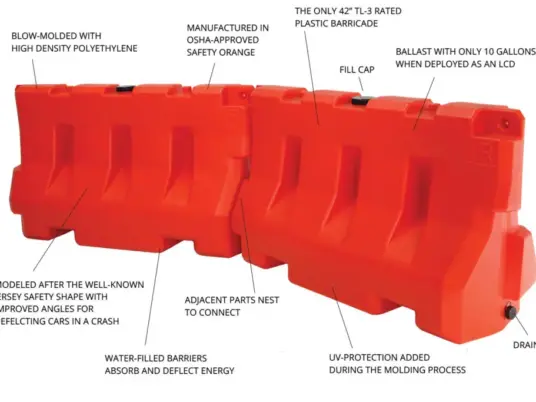

Thanks to rotational molding, this jersey shape barricade exhibits exceptional environmental durability and overall reliability. As a result, it has been successfully deployed to locations such as northern Alaska and Canada, withstanding severe weather conditions. The jersey shape barricade is also a traffic and construction staple, and they have been used across the world in a wide variety of scenarios, consistently exceeding expectations.

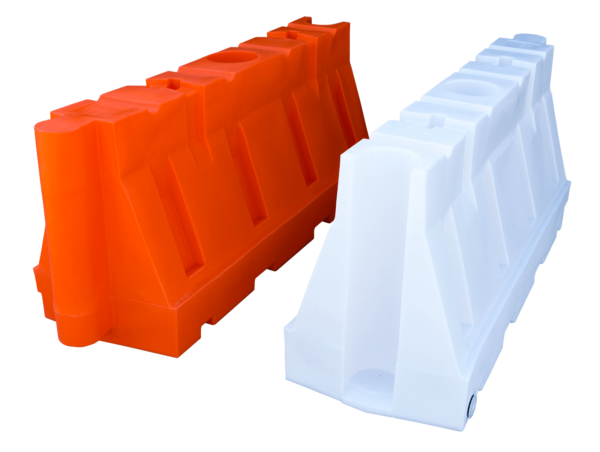

Additionally, it is ideal for use as temporary or semi-permanent security applications in low-speed construction zones and for hazard identification. They are chiefly manufactured in OSHA-approved orange, but custom color options are also available.

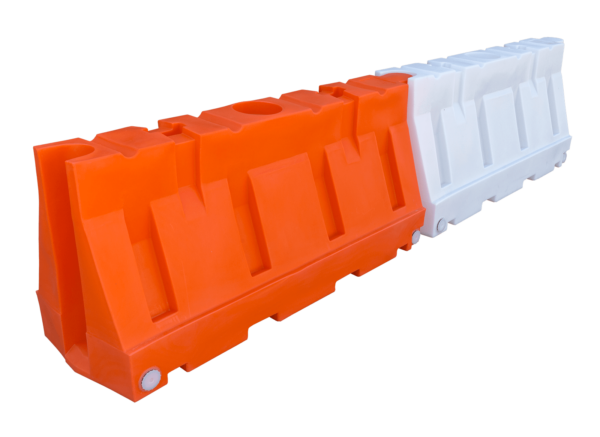

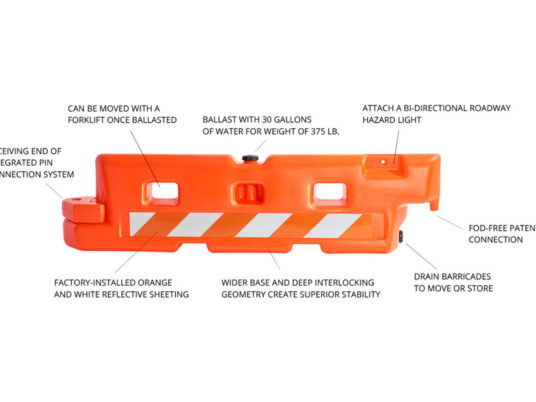

Designed to connect with adjacent units and made to encircle work zones, our JSS barricades are easy to deploy and position around obstacles. Equipped to be filled with water, each barricade can be ballasted up to 900 pounds, but sand can also be used when more weight is needed.

Have multiple applications in mind? Consider optimizing our parts for each one! All JSS barricades can be kitted with reflective sheeting, as well as custom spin welds to accommodate hazard lights.

OPTIONAL CUSTOMIZATION

- High-intensity orange and white reflective sheeting

- Spin welds to accommodate additional hazard lights

Applications

Construction Site Perimeter, Low-Speed Construction Zone, Security Perimeter, Hazard Identification

Specifications

COLORS

- Safety Orange

- Custom colors available (minimum purchase required)

COMPOSITION

- Linear Low Density Polyethylene (LLDPE)

- Rotationally molded

SIZE

- Height: 32 in / 81.3 cm

- Length: 72 in / 182.9 cm

- Width: 24 in / 61 cm

WEIGHT*

STANDARD*

- Empty: 64 lb / 29 kg

- Full: Apprx 900 lb / 3406.8 kg

*Max recommended water ballast is 100 gallons

*Weight calculation based on 100 standard US gallons of water

HEAVY DUTY*

- Empty: 100 lb / 45.4 kg

- Full: Apprx 925 lb / 3501.5 kg

*Weight calculation based on 207 standard US gallons of water

*Max recommended water ballast is 100 gallons

*Weight calculation based on 100 standard US gallons of water

Heavier parts available upon request.